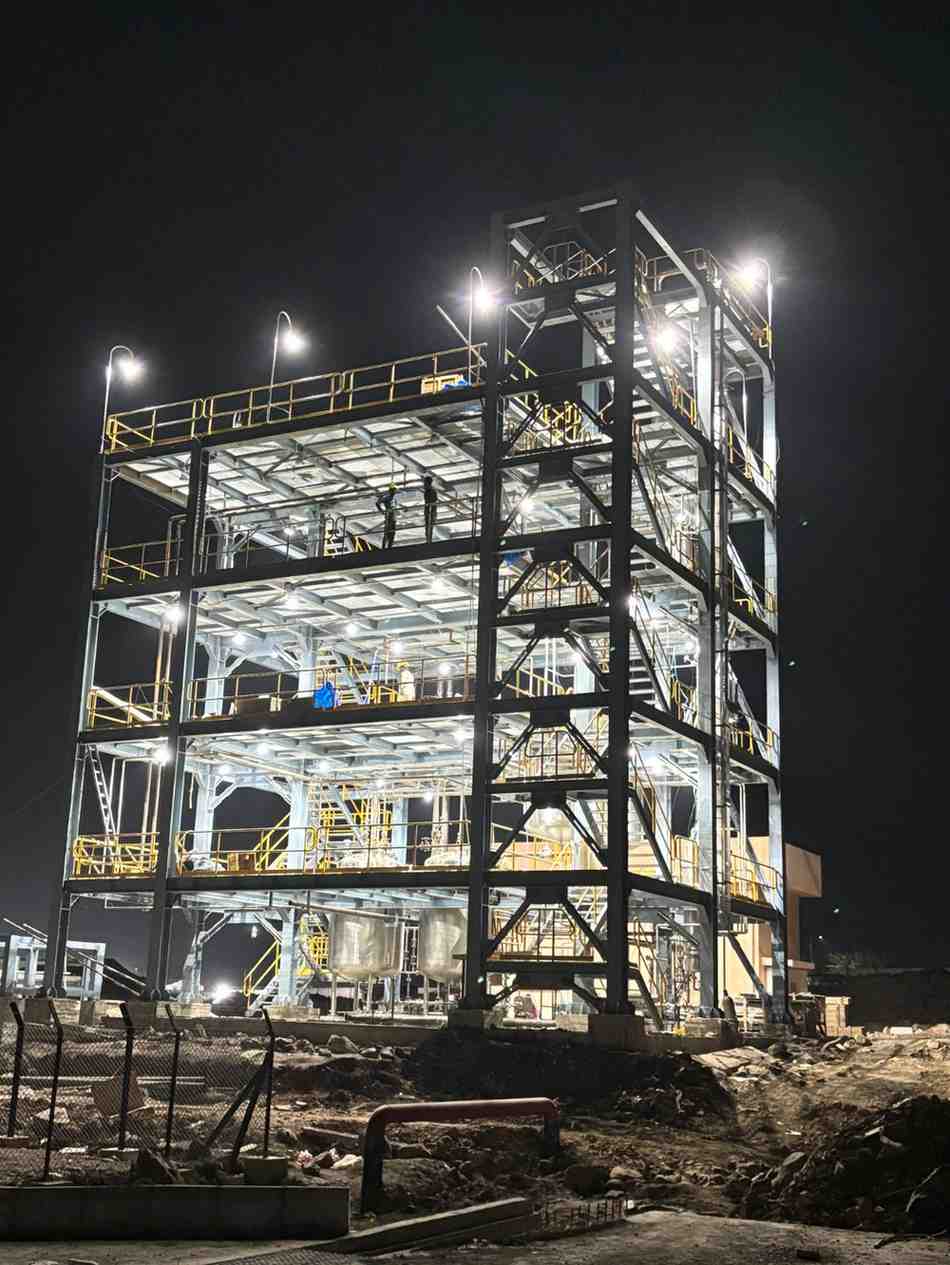

The solvent recovery system from a leading Distillation Manufacturer in India uses a multi-stage distillation approach to recover solvents from waste streams. By leveraging differences in boiling points between solvents and contaminants, the solution is heated to vaporize the mixture, then vapors are condensed into separate liquid fractions across different tanks.

As a reputed Distillation Manufacturer in India, we engineer our Solvent Recovery Unit (SRU) to reclaim and purify solvents from industrial processes. This helps reduce waste, lower operating costs, and supports environmental sustainability.