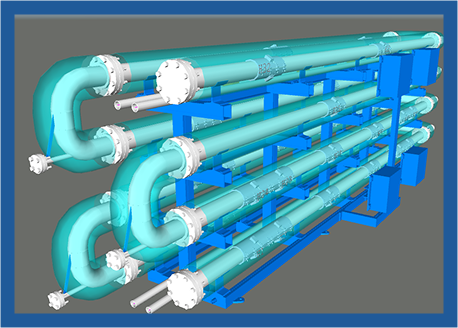

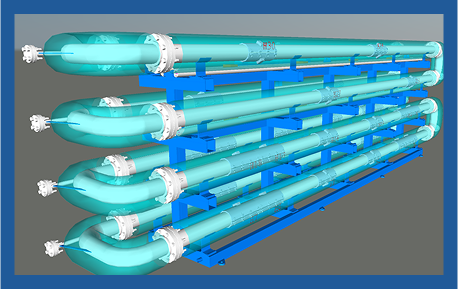

Plug Flow Reactor

An Ideal solution to overcome most of the limitations with traditional multiutility based heat transfer and control system.

Features :-

- Precision Engineering :- Incorporated advanced heat integration systems, reducing energy consumption and operational costs.

- Advance Manufacturing :- Using the latest Technology and rigorous quality control, we deliver reactors that meet the demands of both small-scale and large-scale operations.

- Custom Solutions :- We offer customizable options to fit specific process requirements, helping you achieve unparalleled efficiency and effectiveness in your operations

- Sustainability Focus :- Our reactors are designed with energy efficiency and minimal environmental impact in mind, aligning with your sustainability goals.

Plug Flow Reactor Working Principle

Plug flow reactor works by oxidizing alcohols & other organic compounds to produce fine chemicals like; pigments & dyes. The fluids in this reactor move in a continuous & uniform manner throughout a pipe or tube. The reactants enter at one end of the reactor to flow throughout the reactor and exist at the other end.

Key Features

The key features of a plug flow reactor include the following.

- Unidirectional Flow :- In PFR, the reactants as well as products travel in a single direction along the reactor’s length without back-mixing.

- Concentration Gradient :- The reactant concentration & products in this reactor change with the reactor’s length although it is consistent across any section vertical to the flow.

- Residence Time :- Residence time a separate reactant volume that is spent within the PFR is called residence time and is stable for all volumes.